your journey

How SAP S/4HANA Enables Digital Transformation in Supply Chain and Manufacturing

This is a great article featured on SAP Insider earlier this year. Worth a read…

by Michael Lipton and Amr El Meleegy

SAP S/4HANA Supply Chain and SAP S/4HANA Manufacturing allow companies to gain visibility into real-time market conditions and production efforts and then react to that information with the speed required to deliver products that customers want with the efficiency they need.

Evolving market dynamics and technological innovations are driving a digital transformation across every industry and line of business — and the supply chain is no exception. With more products and services available than ever before, consumers and business customers are increasingly empowered. No longer will they accept whatever product is on the shelf. Now they want it personalised to their exact specifications, delivered to their door quickly, and with sterling customer service should any issues arise. Today consumers can design a suit tailored specifically to them in less than 30 seconds using only their mobile phone. Similarly, electronics configured to consumers’ individual specifications can now be delivered directly to them. If a company can’t meet these evolving expectations, customers can turn to any number of competitors, from long-standing rivals to emerging start-ups. And, supply networks are increasingly distributed and globalised, making responsiveness to demand more challenging.

In such a dynamic marketplace, companies need comprehensive access to accurate, real-time information about their enterprise — and about their customers, suppliers, and competitors. With the right information, businesses can be agile enough to produce and distribute personalised products with shorter lead times and smaller runs — even down to a lot size of one — and ensure that they can meet customer demand while keeping costs under control and productivity at a peak. Achieving excellence in this environment requires two important capabilities: visibility into operational, customer, and market data; and speed across the extended supply chain to react to changes in demand and supply.

With SAP S/4HANA as the digital core, customers can build a foundation for extended supply chain visibility and speed. Since the release of the SAP S/4HANA update in November 2015, the digital transformation capabilities of SAP S/4HANA, including simplified data structures and business processes and personalised user experience, are now being pushed out end to end throughout the enterprise across finance, manufacturing, procurement, and the supply chain. SAP S/4HANA Supply Chain and SAP S/4HANA Manufacturing allow companies to gain visibility into real-time market conditions and production efforts and then react to that information with the speed required to deliver products that customers want with the efficiency they need.

Achieving Real-Time Visibility

Enhanced visibility in SAP S/4HANA stems from innovative technological changes in the solution. Multiple levels of data structures and aggregations are removed, allowing material data to be available in real time and reducing latency and inaccuracies in understanding supply and demand. This allows for the status of production, procurement, and inventory to be available in real time, and for the latest demand signals to be factored into planning decisions. With fast SAP HANA-based materials requirement planning (MRP), planning can be run more frequently, reducing inventories and increasing responsiveness. Further, users can access critical operational analytics and information to support decisions in real time. Embedded analytics — a core concept of SAP S/4HANA — means that business users can evaluate analytical views of the same data that is present in the execution system in real time. Users no longer have to wait for analytical data to be available — and no longer will their analysis be based on outdated data.

These enhancements deliver benefits across various supply chain processes and functions. With embedded analytics, segmentation and policy management become easier. In areas such as inventory management, business users get visibility into slow-moving items, supplier lead times, and production patterns, allowing them to make decisions that can increase inventory turnover. This inventory visibility is further increased by the ability to instantly execute goods movement and back-flushing update processes, enabling faster, more accurate re-planning and order promising.

The same holds true for production. Finite production planning and scheduling will allow users to quickly re-plan when faced with potential production issues or material availability gaps, which are then surfaced to production controllers as alerts on their dashboards, allowing them to manage by exception. Additionally, users can simulate the impact of varying production decisions on delivery dates, reducing uncertainty and risk and improving business outcomes.

Consider the example of a car manufacturer with seven different car models, each requiring an average of 3,500 materials to be produced. With a daily production of 500 cars, the manufacturer has to process over 10 million material postings per day. The technology limitations of the past didn’t allow for such a large number of transactions to be processed in real time, leading a manufacturer to postpone goods movement postings until after production. This meant that during production, the manufacturer didn’t have accurate and full visibility into its material ledger to effectively respond to production issues that might arise. This led to suboptimal production decisions and increased inventory safety buffers to accommodate for the lack of visibility. Now with SAP S/4HANA, postings can run in parallel, giving the manufacturer real-time visibility into its material ledger and allowing it to respond more accurately to production issues and alerts and reduce its safety stock.

Pairing Visibility with Speed

Visibility gives you insight into when supply and demand are out of balance, but this visibility is only valuable if you can act fast enough to respond to the information. Once you’ve detected a supply and demand issue, your company must rapidly evaluate alternative scenarios for responding, select the best one, and execute.

With SAP S/4HANA Supply Chain, any supply or demand change, such as a promotion that generates higher-than-forecasted demand or a disruption in supply due to a late delivery, can be quickly propagated up and down the supply chain to detect imbalances and simulate alternate scenarios. For example, companies that receive large order batches overnight often have challenges in processing these volumes quickly. This is particularly true when more customers are requesting same-day shipment. In SAP S/4HANA Supply Chain, multi-line orders are processed quickly and efficiently, dramatically shortening this latency.

These benefits extend to product lifecycle management (PLM) as well. With the enhanced PLM capabilities in SAP S/4HANA Supply Chain, the design process is aided by context-relevant product data, real-time product analytics, and product definition. All departments can benefit from working with more — and more vital — information, orchestrating processes and standardising efforts across various business functions.

Personalised UIs for Business Users with SAP Fiori Cockpits

Usability is key for adoption and for intuitive decision making, which is why SAP developed SAP Fiori user interfaces (UIs) to simplify the user experience of SAP software. In addition to the simplified business processes and embedded analytics in SAP S/4HANA, the influence of SAP Fiori makes for reimagined cockpits. These mobile-enabled cockpits are specifically designed for different types of users, from production planners and delivery managers to inventory managers and warehouse clerks. These users can now harness all the insights available in SAP S/4HANA Supply Chain and take appropriate action with ease.

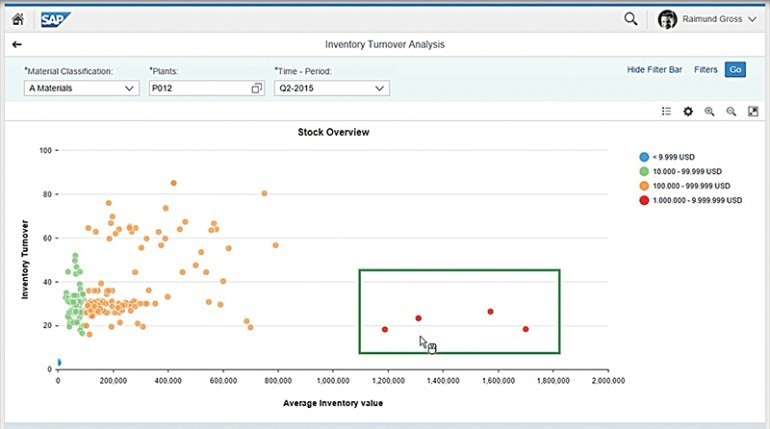

Consider as an example the new MRP cockpit. Controllers can now analyse inventories across multiple plants to identify material shortages. This allows controllers to get full visibility into their inventories and make informed decisions of whether to move materials from a nearby warehouse to fill the shortage, or order new materials from a supplier that could guarantee on-time delivery to meet production orders. As another example, the inventory management cockpit includes new graphical tools that allow managers to plot inventory costs against inventory movement, allowing them to instantly identify high-cost, slow-moving items (see Figure 1).

Figure 1 - With SAP S/4HANA, you can quickly increase inventory turnover by easily identifying high-cost, slow-moving items and taking immediate action

End-to-End Integration

In addition to enabling visibility and speed across the extended supply chain, a significant advantage of SAP S/4HANA is the end-to-end integration that can occur once finance, supply chain, manufacturing, and procurement are all integrated into one system. For example, in Integrated Procure to Pay scenarios, an MRP controller can place an order requisition for a material in shortage that flows seamlessly to procurement for approval and into SAP S/4HANA Finance as accounts payable.

The Road Ahead

Looking forward, we will be extending these innovations to other parts of SAP’s extended supply chain portfolio. These concepts we’ve discussed around improving integration and analytics will extend further and include capabilities such as extended warehouse management, transportation management, integrated business planning, and complex assembly manufacturing.

In summary, SAP S/4HANA Supply Chain and SAP S/4HANA Manufacturing drive greater visibility and speed across the extended supply chain. As a result, organisations will be able to reduce inventory levels through more agility, enhance customer service through reduced lead times and more accurate commitments, deliver new products to market faster, and maintain a competitive advantage.

Share this:

Neil ran his first SAP transformation programme in his early twenties. He spent the next 21 years working both client side and for various consultancies running numerous SAP programmes. After successfully completing over 15 full lifecycles he took a senior leadership/board position and his work moved onto creating the same success for others.